|

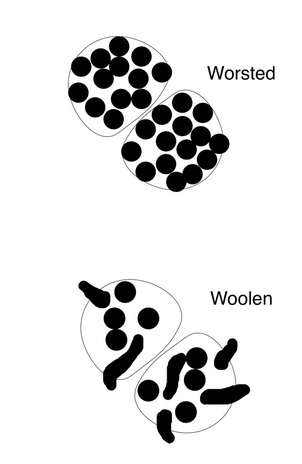

Classically speaking there are 2 types of yarn. Woolen spun, and Worsted Spun. Back in "Ye Goode Old Dayes" all spinners would process their own fleece (or have a small child, or hefty man do it for them; more on that later...) and then use one of 2 spinning types to produce 2 very different yarns. Roll forward to modern times, and the wider variety of spinning fibres we have on offer and things aren't quite so clear cut, but Woolen and Worsted are still useful things for todays spinner to wrap their head around. It's a wordy blogpost, and heavy on video content, because nothing beats seeing these techniques carried out. We'll start off with what the yarns feel like. Woolen yarns contains lots of air, they're light, fluffy, and will often have small ends of fibre poking out of the yarn structure. They're incredibly elastic and bouncey. Jamiesons and Smith 2-ply Jumper weight is a classic commercial example of this type of yarn. Worsted yarns are smooth and dense, they tend to drape well and be much more lustrous. Many commercial yarns are spun in this way, particularly sock yarns. The 2 skeins below were spun using the 2 different techniques, you can can see how much smaller the woolen skein is, but when held under tension will stretch out to the same length as the worsted skein. Why are they different? Well it's all a matter of different fibre preparations, and different spinning techniques. Woolen spun is traditionally spun from carded rolags (this was the job small children carried out). It's then spun with the twist entering the drafting zone in a long draw technique. This video of a Navajo Weaver has long been a favourite of mine. You can see her producing rolags, and then using a navajo spindle to do a form of long draw. Carding, and the rolling in to a rolag creates a spiral of wool fibres wrapping round the tube. You then spin using a long draw technique that maintains that rolled structure. The yarn isn't smoothed, it's simply stretched out like a piece of chewing gum, that traps lots of air in the yarn, and makes it very bouncey and elastic. There are various form of long draw, some make more air filled yarns than others, but the one thing they have in common is that drafting backwards motion, allowing twist to enter the drafting zone. As a beginner it can require a bit of faith, we're generally taught to spin using a short forward draw, where letting twist past our front pinching hand can make it very hard to draft. This method requires twist to be be present however, as it's the twist in the drafting zone that controls the yarn thickness. Once you get going it's very easy to make a surprisingly consistent yarn using this method, as the yarn thickness almost becomes self controlling. Twist naturally navigates to thinner points, and those parts won't draft out further as they have enough twist to hold together. The thicker parts have less twist, and as you pull back they will become thinner, the twist travels in to them and the yarn becomes even. Historically this yarn was spun on Great Wheels. These wheels existed long before wheels with treadles, and because one hand was required to turn the wheel you needed to do a single handed drafting technique. They were an incredibly efficient way of producing a lot of yarn, very quickly. Long draw is still may favourite technique when I need a quick skein of yarn. Worsted Spun requires a very different fibre preparation, and spinning technique. While woolen spinning is all about trapping air, worsted does the exact opposite. Instead of carding the fibres they're combed. Hairs are aligned to be parallel, instead of being rolled up to perpendicular to the direction of the yarn. Twist isn't allowed in to the drafting zone, and a short forward draw is used (this is the most common technique most modern spinners use). Combing was traditionally done on large heavy combs, and was done by men. These are actually a scaled down version of the historical combs, but having handled a pair I can tell you that they're still seriously heavy to handle. As modern spinners we can now get some much smaller and lighter combs, but combing is still a real physical workout. No need to go to the gym if you do an hours wool combing!

So what about for the modern spinner? If you're willing to process your own fibres then you can create a true worsted or true woolen fibre. Providing you're willing to get the wool combs, or the carders out. However, what if you only want to work with commercially processed fibres, or prefer to drum card? In between the 2 true extremes of worsted and woolen is a sliding scale going from fluffy and air filled, to dense and lustrous. You can mix and match fibre preparations to dictate where your yarn falls on that sliding scale. Commercial combed top (the sort that most dyers use even if they call it roving) is most similar to the hand combed top. If you spin using a short forward draw you will make a worsted yarn. If however you spin from the fold the individual hairs will be bent in half and you start to trap more air in the yarn. Throw in a long draw drafting technique and you can still make commercial combed top in to a surprisingly lofty yarn. If you make faux lags and spin long draw you can start to head towards something that looks and feels very similar to a yarn made from carded rolags. Carded Batts are a hard one to wrap your head round. We tend to hear carded, and think of the rolags we make from hand carders, but when you really look closely at a carded batt the fibres run parallel along the length of the batt. If you just pull off strips and spin from one end then the yarn structure will be much closer to worsted than it is to woolen. However, all the same tricks you can employ to alter combed top apply to batts as well. True Roving is a bit tricky to get hold of, but wonderful to spin. It's a commercially processed fibre, but rather than being combed it's carded and peeled off the carding drums in a long spiral of fibre. The way that it's made tends to trap more air in it than combing, I tend to think of it as a halfway house between commercial combed top and hand carded rolags. Spun with a short forward draw it will still contain fibres that are mostly running parallel to the yarn length, but when spun using long draw you can create a yarn with a lot of air trapped in it. So what difference does it make, why bother to think about spinning technique and processing type before spinning?

Because it can make a massive difference to the type of yarn you can produce. Comparing a woolen spun yarn and a worsted spun yarn is like comparing chalk and cheese, they feel so very different and will do different jobs. A lace patterned shawl will have its holes more obscured by a woolen yarn and it won't hold a good block, but a jumper made of worsted spun yarn can be very dense and heavy, particularly in thicker yarns. It's worth doing a bit of experimenting to seeing how a fibre behaves when you spin it using different techniques. Both swatches below were spun from BFL commercially combed top. The Woolen one was spun from fauxlags using a long draw technique. The Worsted one was spun from the end of the top, using a short forward draw. As ever, pictures only say so much, you need to feel these yarns to really appreciate the difference.

Jude

28/5/2016 01:10:39 pm

Thank you so much Katie. As a very new spinner (wheel) I found this article so informative and easy to understand. The difference between worsted and woollen and how to achieve either of them has been my biggest question ..... Loved the first video, and your video was brilliant, thank you so much. 9/6/2016 10:18:07 pm

Great explanation, i aways spin long draw and card my alpaca, tearing long strips off of the batt, i would be interested in working out what type my yarn is. Thanks

Katie

10/6/2016 07:52:09 am

Ok, first up lets look at how the fibres are running in to the yarn. Are they going in parallel or perpendicular? 8/9/2016 09:10:10 am

Thanks for explaining the difference, it's interesting to see those subtle contrasts between the stitching!

Seedpodthreads

4/3/2017 11:32:52 pm

Thanks for the good explanation. I have just started spinning using a Navajo type spindle and I was unsure that I was l on the right lines. It seems that I am and have produced a woollen yarn. Comments are closed.

|

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed