|

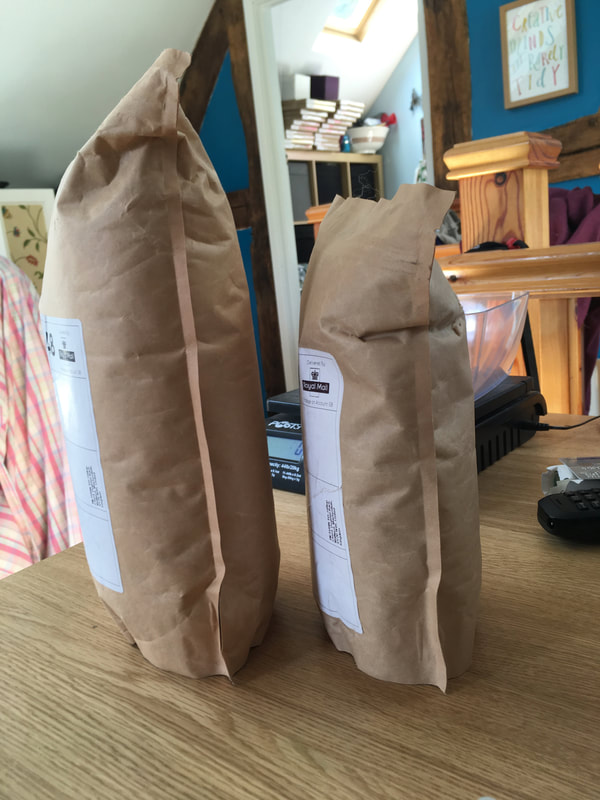

Around a year ago I wrote a blogpost about the packaging that use. I've always tried to use packaging responsibly, from the very first day when I set up the business, and have always tried to make sure that you receive fibre in the best possible condition. If I put fibre in a piece of packaging it's because I think it needs to be there. Tissue paper might be more recyclable, but it's fundamentally useless at doing anything other than looking pretty. As a small business I've always been limited by what packaging products I can buy. I might buy in relatively large amounts, but I'm no where near large enough to be commissioning custom designed packaging.. Finally however the packaging industry seems to be catching up and there's now a huge amount of biodegradable items on the market! Of course newness of products, and limited availability means that nearly all these items are more expensive, but for the most part it's not by a vast amount. One thing that's become very clear when I compare my accounts, everything I buy is costing more than it was 2 years ago. I didn't pass on the postage price rises in April this year,so I suspect that I will need to charge slightly more for postage once I swap to using all the new packaging. I've used biodegradable mailers for a long time, but I'm now using ones that are biodegradable, and made from recycled material. The first orders using these mail bags went out this morning, and as I run out of stock of the other sizes I will gradually switch over to using them. If you get one of the new bags the biodegradable additive means that they are not recyclable, they need to go in with your normal waste. If you have a compost heap you can also add them to that. I've also been on the hunt for a more environmentally friendly version of the clear grip seal bags that I use, and finally one exists! These are still re-usable, but I can also heat-seal the top, meaning them can go through the postal system with no further packaging. These pair of bags have been travelling backward and forward through the UK mail system a few times to check how they stand up to the abuse of the postal system. They're still waterproof, but are now biodegradable so will break down in to compost. The outer is made from renewable wood pulp starch. These bags will compost, but I'd recommend including them with your regular rubbish because a household compost heap will take a while to break these down. Once they arrive you can tear off the top, off over the pretty contents, and still use the bag for your own fibre storage. I also did this to one of them....

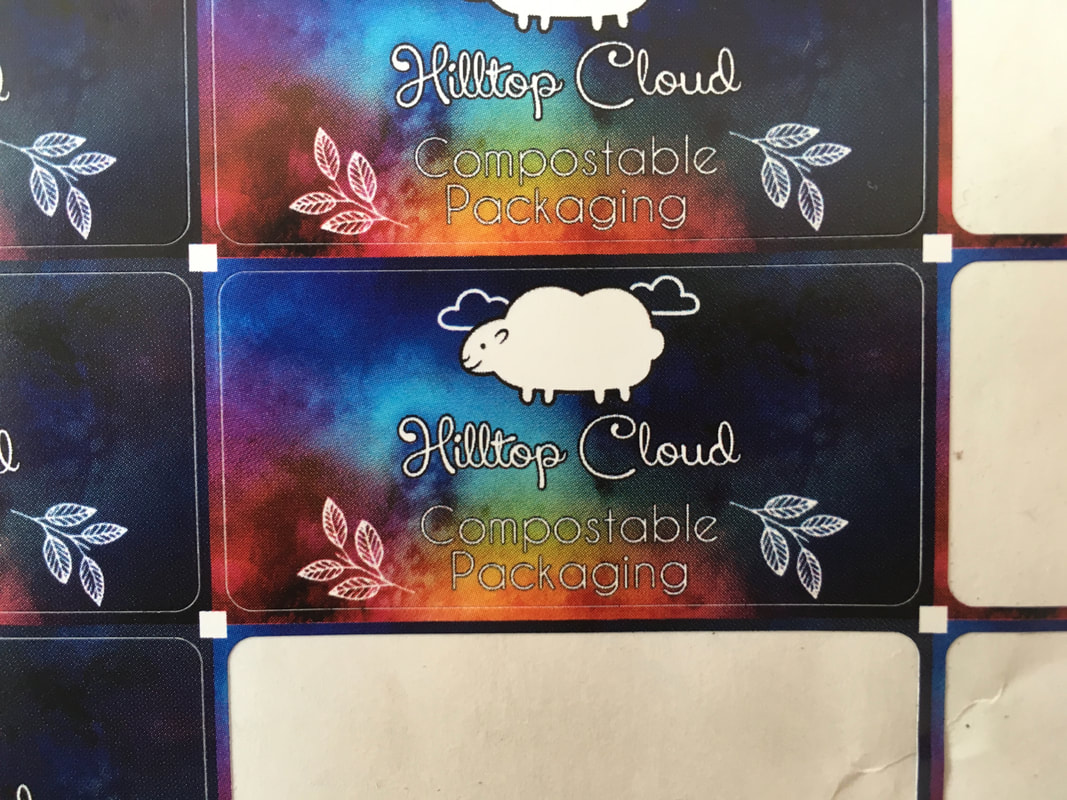

Finally, I'll also be swapping over the cellophane bags that I use for things like Gradient Packs, and any other form of fibre that uses lots of small chunks of fibre. I can now get a clear film bag made from cellulose film (wood pulp from managed plantations, which again means they're compostable. A few fibres have already been sent out using these bags, because I have ordered more bags than you can imagine to work out the size and type that works best! I do sill have quite a decent stock of the old bags, but if you get one of the new ones, it will have this sticker on the seal. You won't see all of the new packaging all at once. If I still have a few hundred bags left then it would be just as damaging for me to throw them away as it would for me to send you the fibre in an old style bag that you can then reuse.

The only form of packaging that will remain as non-biodegrable plastic is the small label bands I use on the fibre. I have tried other versions, but when you rummage around in a sack of 50 braids to find the right one strung labels tangle up, the string rubs on the surface of the fibre, and the hole in the card breaks. Card and staples cause similar issues. Some dyers individually bag every single braid, but I'd rather go the route of a single small piece of non-biodegrabale plastic, than use large numbers of bags, particularly because so many of you order multiple braids of fibre. I'm very limited in storage space, so can't hang everything up, so my labelling solution has to be robust.Eventually I suspect that tyvek wristbands will be made out of a new material, but for now it's just a case of waiting for the manufacturers to catch up with consumer demand. We'll still be doing our bit to re-use or recycle the packaging that comes to us, there are 3 of us working from home, and we often don't fill our 240L rubbish bin when it's collected every 3 weeks, so I think we do a pretty good job. |

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed