Pre-Wound warps for weaving. Hand Dyed in Wales

These warps are hand wound here in Wales before being dyed.

We use professional grade acid dyes (these are non-toxic, and safe for the environment), and provide excellent colourfastness, and resistance to fading. After dyeing all warps are rinsed in hot water with detergent, and then rinsed again in hot water. We get no dye run off during this process, however using the water that comes out of your tap, and using a different detergent is not unusual to get some bleeding of certain colours (saturated blues and turquoises). We recommend using cool water and a pH neutral detergent. You may also wish to use a colour catcher, if any dye bleeding would cause serious problems with your finished project.

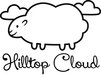

The dyeing process requires that the ties on your warp are much looser than that used normally. Ties that are tight would cause white spots during the dyeing process. We have done extensive testing of our hand dyed warps on shafted and rigid heddle looms, and have found no difficulties with tangling. Your warp will have the following ties-

We use professional grade acid dyes (these are non-toxic, and safe for the environment), and provide excellent colourfastness, and resistance to fading. After dyeing all warps are rinsed in hot water with detergent, and then rinsed again in hot water. We get no dye run off during this process, however using the water that comes out of your tap, and using a different detergent is not unusual to get some bleeding of certain colours (saturated blues and turquoises). We recommend using cool water and a pH neutral detergent. You may also wish to use a colour catcher, if any dye bleeding would cause serious problems with your finished project.

The dyeing process requires that the ties on your warp are much looser than that used normally. Ties that are tight would cause white spots during the dyeing process. We have done extensive testing of our hand dyed warps on shafted and rigid heddle looms, and have found no difficulties with tangling. Your warp will have the following ties-

The bases used changes on a regular basis, if you have a particular yarn in mind please get in touch.

If you have an idea for a custom dye job on warps, again please get in touch. They can be wound to any length and with any number of ends on a large selection of yarns.

If you have an idea for a custom dye job on warps, again please get in touch. They can be wound to any length and with any number of ends on a large selection of yarns.

If you are a shaft loom weaver and used to using indirect warping then these warps should be ready to be wound on using the method you normally use.

If you are a rigid heddle weaver then the following advice may be of help!

Firstly, do not remove any of the ties until you are absolutely ready to wind your warp. I like the instructions used on the book Inventive Weaving on a Little Loom.

There are numerous You Tube videos available, however not all of them use lease sticks, and these are invaluable to help keep your warp under control. The warp cross keeps the threads in your warp in the same order in which they were wound, and prevents tangling. If you insert lease sticks this helps to spread out your warp and keeps all the threads in the right order. It's a technique that is more commonly used for shaft looms, but will make your life much easier if you transfer this technique to warping a rigid heddle loom. Most of the videos I can find involve you holding the cross in your hand, but this ties you to the loom until you have completed the warping process.

You also have less loom waste if you have a back apron rod which is removable, this allows you to just slide the loops of warp straight on to that back apron rod, and not need to tie a knot. The Syne Mitchel book, Inventive Weaving on a Little Loom details how to alter an Ashford loom to make this possible.

I've also written a step-by-step guide to show you how I wind an indirect warp on to my loom.

If you are a rigid heddle weaver then the following advice may be of help!

Firstly, do not remove any of the ties until you are absolutely ready to wind your warp. I like the instructions used on the book Inventive Weaving on a Little Loom.

There are numerous You Tube videos available, however not all of them use lease sticks, and these are invaluable to help keep your warp under control. The warp cross keeps the threads in your warp in the same order in which they were wound, and prevents tangling. If you insert lease sticks this helps to spread out your warp and keeps all the threads in the right order. It's a technique that is more commonly used for shaft looms, but will make your life much easier if you transfer this technique to warping a rigid heddle loom. Most of the videos I can find involve you holding the cross in your hand, but this ties you to the loom until you have completed the warping process.

You also have less loom waste if you have a back apron rod which is removable, this allows you to just slide the loops of warp straight on to that back apron rod, and not need to tie a knot. The Syne Mitchel book, Inventive Weaving on a Little Loom details how to alter an Ashford loom to make this possible.

I've also written a step-by-step guide to show you how I wind an indirect warp on to my loom.

A rough guide for calculating the sett or heddle size for any of these yarns is to check the wraps per inch. For plain weave use an ends per inch, or dents per inch that is half of that.

For rigid heddle weavers- recommended heddle sizes-

Yarns of around 350-400m per 100g

For an even-weave, tabby scarf with nice drape- 10 DPI heddle

For a denser fabric for a bag or cushion- 12 DPI heddle

Other lace weight yarns of 700-800m per 100g

This may work on the extra fine 15dpi heddle available from Ashford to create an open fabric for a scarf, or will work if you use 2 heddles in combination on other brands of loom.

For rigid heddle weavers- recommended heddle sizes-

Yarns of around 350-400m per 100g

For an even-weave, tabby scarf with nice drape- 10 DPI heddle

For a denser fabric for a bag or cushion- 12 DPI heddle

Other lace weight yarns of 700-800m per 100g

This may work on the extra fine 15dpi heddle available from Ashford to create an open fabric for a scarf, or will work if you use 2 heddles in combination on other brands of loom.

Hints to maximise your hand dyed warp-

- Try to create a warp faced fabric, this means using a finer sett than you might normally use

- If you have a multi-shafted loom pick a draft that has warp floats.

- Use a weft that is slightly finer than your warp yarn

- Think about colour interactions between your warp and weft, this blogpost may help.

Samples

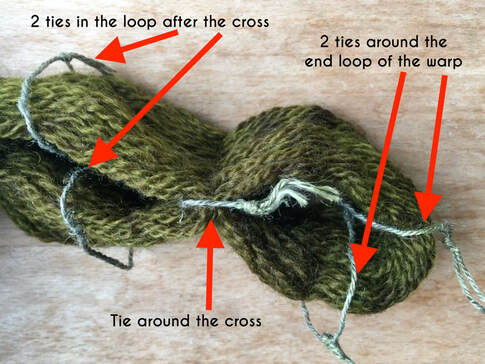

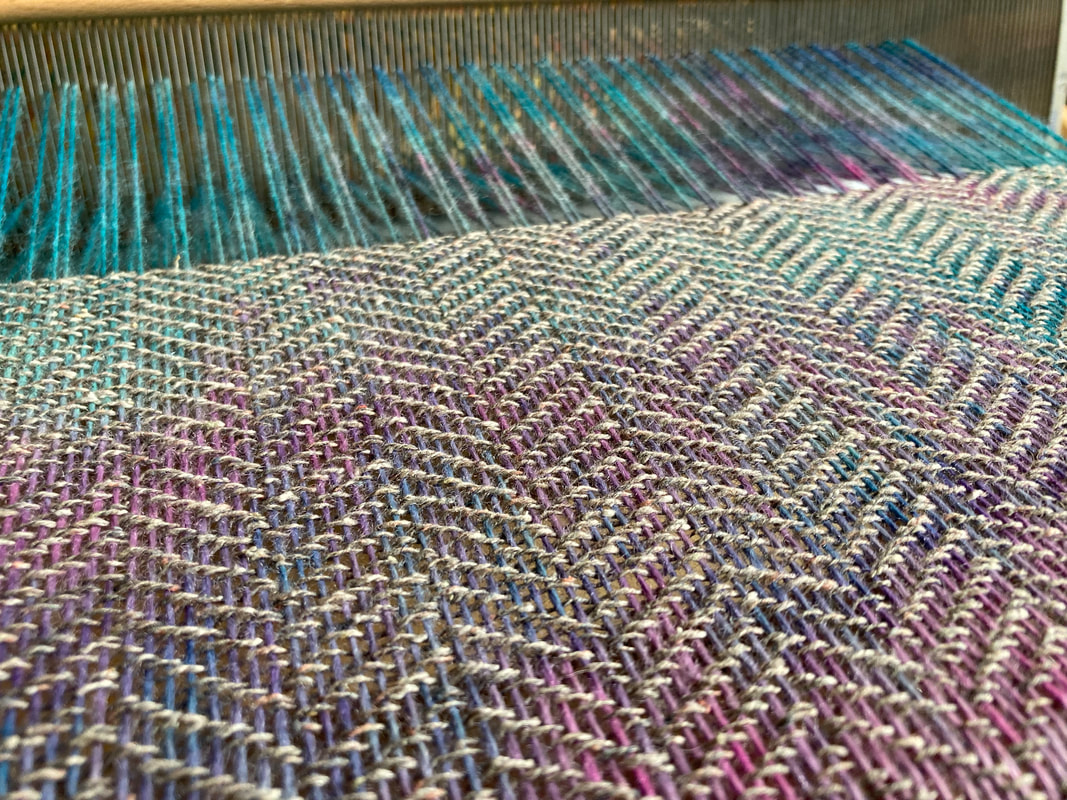

The following samples were woven to test out the dyeing techniques, and to ensure that your warp will be simple to wind on to your loom.

The following samples were woven to test out the dyeing techniques, and to ensure that your warp will be simple to wind on to your loom.

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |