|

A short while ago I spent a lovely morning exploring the mines in the hills above Machynlleth. People tend to look at where I live and think it's wild and untouched, but even up in the high hills man has had an impact. Mining has happened in Dylife since Roman times, and only stopped in the early 1900's. It's a really exposed site, right up in the hills, but the lead seams were very rich. I grew up in the Peak District, and am used to the lead mines there, which have now been so visited by people going through the spoil heaps that you don't really find anything interesting. That's definitely not an issue here! Nearly every rock you pick up is heavy with lead, and if you break them open they shine with lead ore. As well as lead there are lots of other interesting bits of geology, so many inclusions of quartz, and lots of fools gold.  The site was nearly completely abandoned and stripped. Even the dwellings are no longer there, The Star Inn pub remains, and two chapels have been converted to houses. The church was dismantled, only the headstones remain. Most of the evidence of mining has gone as well. It was home to one of the largest waterwheels in the UK (Rhod Goch), which was 63 feet (20m) in diameter. Some evidence says that when the mine closed it was dismantled and shipped over to Canada. If you walk up the valley, following the stream you do find this... It's a giant pumping mechanism to remove the water from the mine. Lower down the valley there's more water management. A pipe to carry water, but it's made from a hollowed out log rather than planks. In winter during times of heavy rain this whole area ends up being flooded, so you can see why they needed to focus on water drainage.

Lots of people enter the world of spinning with the aim of spinning for socks...

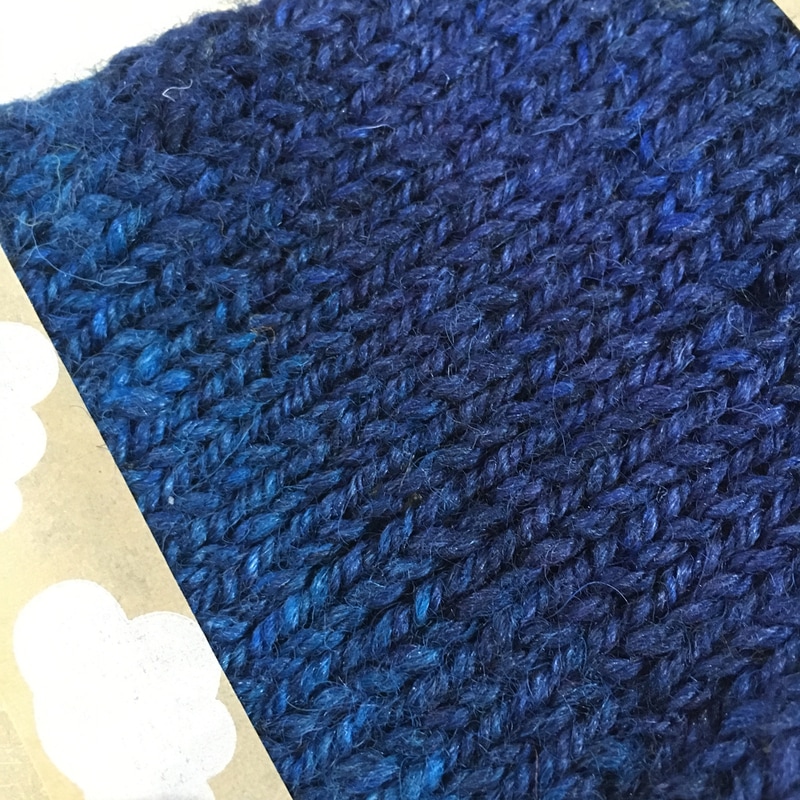

Then they fall down the rabbit hole and discover just how many things go in to making a good sock yarn. Before you even get in to fibre choice, there's the issue of number of plies (more is better), wether to go classic 3-ply, or modern chain ply (tests seem to show there's very little difference), or even to use opposing plies. A good sock yarn needs to have bounce and memory. Otherwise the ribbing at the top bags out, and your socks fall down. It needs to withstand lots of friction, and needs to be able to put up with getting warm and damp. Those are of course conditions for felting. Some people are ok with their socks felting, which is fine providing that doesn't make them shrink. It also removes some of that elasticity. So I prefer a fibre that resists felting. If you want to go pure wool, then Southdown is a really good bet. It resists felting, and has great elasticity. However, it's not great at resisting abrasion. If you have rough feet, or rough patches in your footwear you will get holes. As well as Southdown I always used to offer a Superwash BFL & Nylon blend. This was great, because the superwash treatment resists felting, and it was hardwearing from the nylon. However, it was actually very similar to the Superwash BFL & Ramie base that I adore. So last summer I started experimenting. I still wanted a really machine-washable option (you can put Southdown in the machine, but I wanted a superwash treated fibre, that people could also use for garments). It also needed to be resist to abrasion, and have more bounce than the Superwash BFL.

And the final result... Two swatches. One went through a machine wash pinned to my jeans pocket. The other was unwashed. The stitches still move, and the size remained un-changed. It's a delight to dye as well.

I'm still using British wool, which was important to me. But it's slightly more coarse than BFL (but for your feet that's really not an issue), and is lovely and bouncy. You could still use this fibre for jumpers, cardigans, gloves and hats, it's definitely not Herdwick!

© Copyright Walter Baxter and licensed for reuse under this Creative Commons Licence

The Cheviot Hills are in the border area between Scotland and England, and remind me so much of my own bit of Wales.

By Cheviot_ewe_with_lamb.jpg: Donald Macleod from Stornoway, Scotlandderivative work: Coycan (Cheviot_ewe_with_lamb.jpg) [CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons

The sheep that live in the area are hardy, living on the hills all year round. They have a lovely bulky fleece, with a 3D crimp that makes the fibre bouncey, and hard wearing. The staple length is 4-5 inches, which makes it excellent for worsted spinning, just what you want from a sock yarn.

To add to the strength I've kept the nylon component. It really does help stop holes developing. To help with the dyeing, because Cheviot is a chalky fibre that can be a bit of a pain to hand dye, and to allow me to dye the eye-socking colours some love in their socks I've added some tussah silk. I did a small batch for the online shop a few weeks ago, and also had some for sale at Wonderwool. Thos braids flew off the shelves, so I've dyed another batch that will be in the shop at the start of next week. |

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed