|

It seems that everywhere you look around the garden there's a nest appearing! Remember the House Martin nest from two weeks ago? Well nest number 2 that they were building in the video also fell down, but practise really does make perfect because by nest 3 they have cracked it! I'm particularly taken by the decorative grass seed head sticking out at a jaunty angle! The House Martins aren't alone either, this morning we made this spot... On the top of one of the oak beams that came out of the barn when it was renovated, a tiny nest! I can actually see the nest through the back window of the caravan I use as a dye studio, so when the female came back I could spot it was a Wren. Normally they're incredibly secretive birds, but this one has built it's nest in a really busy spot. We walk past it on a daily basis to get round the back of the workshop, and I'm crashing about in the caravan regularly... Who knows if those eggs will hatch, let alone if the chicks will survive. The birds built the nest there knowing our activities, and have been laying an egg a day with us moving around the nest. The nest itself is absolutely beautiful. A collection of moss, dry grass, sheeps fleece and dog hair combings. Inside are 4 cream and brown speckled eggs. I couldn't make the camera focus on the eggs and not the edge of the nest, and didn't want to spend too long taking a photo. It's a warm day, but the eggs will chill quickly without the female sitting on them. In a couple of weeks there might be some cheeping chicks to keep me entertained while dyeing.

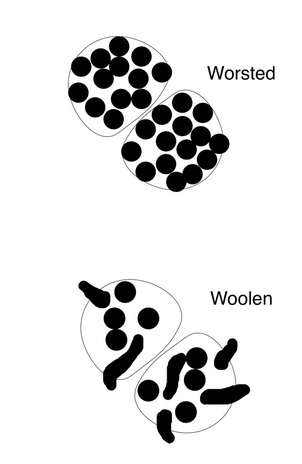

Classically speaking there are 2 types of yarn. Woolen spun, and Worsted Spun. Back in "Ye Goode Old Dayes" all spinners would process their own fleece (or have a small child, or hefty man do it for them; more on that later...) and then use one of 2 spinning types to produce 2 very different yarns. Roll forward to modern times, and the wider variety of spinning fibres we have on offer and things aren't quite so clear cut, but Woolen and Worsted are still useful things for todays spinner to wrap their head around. It's a wordy blogpost, and heavy on video content, because nothing beats seeing these techniques carried out. We'll start off with what the yarns feel like. Woolen yarns contains lots of air, they're light, fluffy, and will often have small ends of fibre poking out of the yarn structure. They're incredibly elastic and bouncey. Jamiesons and Smith 2-ply Jumper weight is a classic commercial example of this type of yarn. Worsted yarns are smooth and dense, they tend to drape well and be much more lustrous. Many commercial yarns are spun in this way, particularly sock yarns. The 2 skeins below were spun using the 2 different techniques, you can can see how much smaller the woolen skein is, but when held under tension will stretch out to the same length as the worsted skein. Why are they different? Well it's all a matter of different fibre preparations, and different spinning techniques. Woolen spun is traditionally spun from carded rolags (this was the job small children carried out). It's then spun with the twist entering the drafting zone in a long draw technique. This video of a Navajo Weaver has long been a favourite of mine. You can see her producing rolags, and then using a navajo spindle to do a form of long draw. Carding, and the rolling in to a rolag creates a spiral of wool fibres wrapping round the tube. You then spin using a long draw technique that maintains that rolled structure. The yarn isn't smoothed, it's simply stretched out like a piece of chewing gum, that traps lots of air in the yarn, and makes it very bouncey and elastic. There are various form of long draw, some make more air filled yarns than others, but the one thing they have in common is that drafting backwards motion, allowing twist to enter the drafting zone. As a beginner it can require a bit of faith, we're generally taught to spin using a short forward draw, where letting twist past our front pinching hand can make it very hard to draft. This method requires twist to be be present however, as it's the twist in the drafting zone that controls the yarn thickness. Once you get going it's very easy to make a surprisingly consistent yarn using this method, as the yarn thickness almost becomes self controlling. Twist naturally navigates to thinner points, and those parts won't draft out further as they have enough twist to hold together. The thicker parts have less twist, and as you pull back they will become thinner, the twist travels in to them and the yarn becomes even. Historically this yarn was spun on Great Wheels. These wheels existed long before wheels with treadles, and because one hand was required to turn the wheel you needed to do a single handed drafting technique. They were an incredibly efficient way of producing a lot of yarn, very quickly. Long draw is still may favourite technique when I need a quick skein of yarn. Worsted Spun requires a very different fibre preparation, and spinning technique. While woolen spinning is all about trapping air, worsted does the exact opposite. Instead of carding the fibres they're combed. Hairs are aligned to be parallel, instead of being rolled up to perpendicular to the direction of the yarn. Twist isn't allowed in to the drafting zone, and a short forward draw is used (this is the most common technique most modern spinners use). Combing was traditionally done on large heavy combs, and was done by men. These are actually a scaled down version of the historical combs, but having handled a pair I can tell you that they're still seriously heavy to handle. As modern spinners we can now get some much smaller and lighter combs, but combing is still a real physical workout. No need to go to the gym if you do an hours wool combing!

So what about for the modern spinner? If you're willing to process your own fibres then you can create a true worsted or true woolen fibre. Providing you're willing to get the wool combs, or the carders out. However, what if you only want to work with commercially processed fibres, or prefer to drum card? In between the 2 true extremes of worsted and woolen is a sliding scale going from fluffy and air filled, to dense and lustrous. You can mix and match fibre preparations to dictate where your yarn falls on that sliding scale. Commercial combed top (the sort that most dyers use even if they call it roving) is most similar to the hand combed top. If you spin using a short forward draw you will make a worsted yarn. If however you spin from the fold the individual hairs will be bent in half and you start to trap more air in the yarn. Throw in a long draw drafting technique and you can still make commercial combed top in to a surprisingly lofty yarn. If you make faux lags and spin long draw you can start to head towards something that looks and feels very similar to a yarn made from carded rolags. Carded Batts are a hard one to wrap your head round. We tend to hear carded, and think of the rolags we make from hand carders, but when you really look closely at a carded batt the fibres run parallel along the length of the batt. If you just pull off strips and spin from one end then the yarn structure will be much closer to worsted than it is to woolen. However, all the same tricks you can employ to alter combed top apply to batts as well. True Roving is a bit tricky to get hold of, but wonderful to spin. It's a commercially processed fibre, but rather than being combed it's carded and peeled off the carding drums in a long spiral of fibre. The way that it's made tends to trap more air in it than combing, I tend to think of it as a halfway house between commercial combed top and hand carded rolags. Spun with a short forward draw it will still contain fibres that are mostly running parallel to the yarn length, but when spun using long draw you can create a yarn with a lot of air trapped in it. So what difference does it make, why bother to think about spinning technique and processing type before spinning?

Because it can make a massive difference to the type of yarn you can produce. Comparing a woolen spun yarn and a worsted spun yarn is like comparing chalk and cheese, they feel so very different and will do different jobs. A lace patterned shawl will have its holes more obscured by a woolen yarn and it won't hold a good block, but a jumper made of worsted spun yarn can be very dense and heavy, particularly in thicker yarns. It's worth doing a bit of experimenting to seeing how a fibre behaves when you spin it using different techniques. Both swatches below were spun from BFL commercially combed top. The Woolen one was spun from fauxlags using a long draw technique. The Worsted one was spun from the end of the top, using a short forward draw. As ever, pictures only say so much, you need to feel these yarns to really appreciate the difference. A few nights ago, I went out to put the chickens to bed. As I left the house through the top door that leads on to the deck, and straight on to the garden (the house is set in to the hillside) I noticed there was a lot of mud in the doorway. I shrugged it off, put it down to the dogs and didn't think too much of it. As I came back in to the house I happened to look up, and spotted 3 House Martins perched on a part built nest. The next morning they were busy flying backwards and forwards with beaks full of mud, and kept me very amused. That afternoon I planned to get the camera out and film them, however, whilst I was eating lunch on the deck, disaster! With a slumph, and a splat the half built nest fell completely off the wall. It was a bit like one of those moments on The Great Pottery Throw Down when someone uses far too much slip, or builds too quickly and the whole lot just collapses on itself. Most of the nest was now sat right on top of my outside light... I did wonder if they would give up, and I'd missed my chance to take photos and film them. Luckily however these birds aren't quitters! This time they appear to be going more slowly, just a bit is being added each day. At one point every time I went out with the camera they decided to go off feeding instead of nest building, but eventually I got there. It's filmed on my regular camera on a tripod so isn't crystal clear, and you'll be relieved to know I've removed the sound because no one needs to hear just how noisy the countryside actually is... In these 5 minutes there are cars, Dad chainsawing, a racket of garden birds, and a low flying RAF jet. Here's a close up of the mud that fell off. Yet another use for Welsh Mountain wool, apparently it makes a very useful nest strengthener!

They stay here until September or even October before migrating back to Africa, so they can afford to take their time as they sometimes manage to squeeze 3 broods in to the summer season. If this nest doesn't work out then we might put up a man-made nest this winter but we can't do that now as it would disturb them. If they do manage to build a nest I might have a go at doing the BTO House Martin survey as they're in decline as a breed, though seem to be doing well out here. These birds will have come over the valley where a whole colony nest on the side of a farm house. When the weather is this wonderful, and you live somewhere this beautiful how could you not sneak off from work and get out to enjoy the spring? This photo is taken just north of Dolgellau, looking south towards Cadair Idris, with the Mawddach Estuary below. You can just make out the wooden toll bridge that crosses the river at Penmaenpool. We parked at the valley bottom, and you then have to climb up hill very steeply through the woodland. You end up in an RSPB reserve which is also a former gold mine. The remains of the mine buildings are slowly being hidden away by the woodland. This was the real reason for visiting though. I remembered from a few years ago that there was a beautiful bluebell glade. The perfect spot for a bit of doggy posing... and joyous rampaging when they'd been told they'd sat for long enough! It's a beautiful spot for a walk, filled with very ancient woodland, including some stunning oak trees. For now, it's back to work, though at least I only have to turn my head to see some beautiful scenery, and marvel at nature. This weekend a pair of house martins started making their nest just above my office door. Wonderful to watch, though the splats of mud they're dropping on my freshly cleaned window are less appreciated! Something that pops up on my twitter feed occasionally is discussions about how we only show edited glimpses of our lives online. I like sharing the pretty photos, but I also happen to find the less pretty ones equally interesting, even if they are more graphic. With that in mind, if you don't want to see what happens to a vole when it dies stop reading now... With my scientist head firmly screwed on I find it fascinating, and I suspect others will too. This shrew is going to provide food for all sorts of wildlife. The orange and black spotted beetle is a Sexton beetle, the black ones might also be a different type of sexton beetle, but they don't seem to be the right shape for the photos I can see, and my google-fu is failing me, they also look like dung beetles, but dung beetles eat poo, and not flesh. The little rolled up ball at the bottom left is a pill millipede.

The weather has really warmed up, and the plants seem to have taken it as a challenge to see just how quickly they can go from bare, to full leaf. This little patch of woodland had clearly been managed in the past, lots of coppiced trees, but now had a gentle air of neglect. On the river bank the wild garlic was out, which produced an odd craving for pasta at 11am!

Over on the Hilltop Cloud Ravelry group a discussion topic popped up about ply number, and what would be best for a cardigan with cables... Of course common wisdom is that you should use 2-ply for lace, and 3-ply for cables. But a picture speaks a thousand words. These are all swatches I made up for my Spinning with a Purpose workshop, over time I'm sharing the swatches on via a series of blogposts, you can read the previous posts here. We'll start off with the lace. Here's a side by side shot. 3 ply is on the left, 2 ply on the right. Same thickness of yarn, same needles, but the holes are definitely more visible on the 2ply swatch, and the decrease columns more visible on the 3ply swatch. Close up of the 2-ply swatch. You can see at the point where the strands wrap over at the yarn over they nestle together. 2-ply yarn isn't actually round, it's more like an oval shape that spirals, that allows the strands to sit together nicely. In contrast on the 3-ply swatch those twisted sections take up far more room, and that means the hole you create from the yarn over is far less visible. What is very apparent though is how much that centred double decrease pops proud of the surface, and that feature is what makes 3-ply yarns a star for cables and textured stitches. Texture is very hard to see in photos, trying to demonstrate just how good a 3-ply is at cables is somewhat tricky, I wish you could all feel these swatches for yourselves. This is a standard 3x3 cable, together with a column of twisted stitches. In both cases the motif really pops off the surface of the knitting. In the 2-ply it's ok, partly because I like a firm tension for my knitting, but it lacks that 3-D pop. A shot from side on hopefully demonstrates what I'm on about... 3ply on the left, 2 ply on the right. It's not that the 2-ply version is rubbish, just that it lacks the wow factor that adding the extra ply produces.

So there you have it, sometimes the collective wisdom is wrong, but in the case, most definitely not. 2 ply for lace, 3 ply for cables! |

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed