|

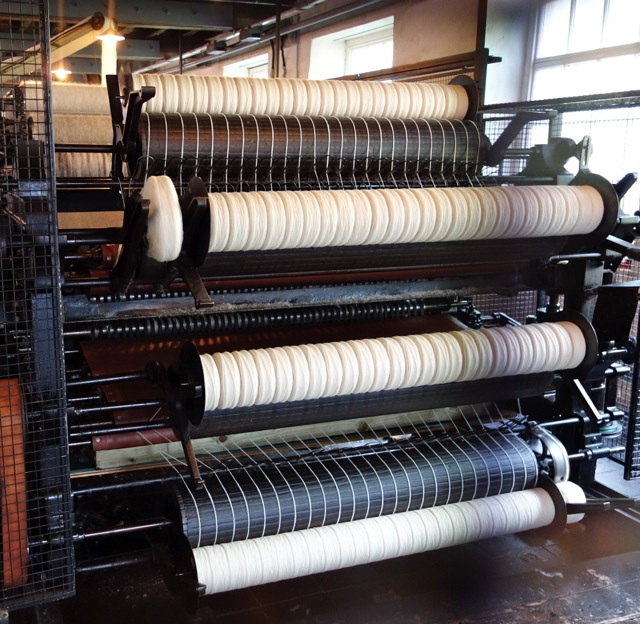

Last week, I took a day off to head towards south Wales, a friend needed a chauffeur, and what's the point in being self employed if you can't take a day off mid week. I spent the morning reminding myself of civilisation, doing things like drinking coffee, and eating cake, and food shopping in Marks and Spencer. For lunch, we called in at the National Welsh Wool Museum. Wool was a vital part of the Welsh economy, sheep were, and still are just about the only thing that do well in many of the hills of Wales. There used to be Woollen Mills all over the country, very few are still functional. A sign of the rise of petrochemicals, and the increase in labour costs making it un-economical for them to be run as profitable businesses. Inside an old mill building there's a treasure trove of old machines, most of which still work, that are set up to show people how the wool is processed from start to finish. We timed our arrival with a coach full of American tourists, so got to see many of the machines working. (Many of the processing machines are fenced off to prevent damage to visitors, so there are a few lines on some of the photos) The closest thing to this machine in hand spinning speak is a picker, very sharp metal teeth tease open the locks, preparing them for carding. Sort of like you do with a flicker when preparing to put a fleece through a drum carder. You can see the sharp teeth on this photo. The wool used is a mixture of Welsh lambs wool, and merino. It's now washed elsewhere, as far as I'm aware there's only one place where wool is commercially scoured on a large basis left in the UK. It's very, very clean by the time it goes through the machines, all the lanolin has been removed, as it would gunk up the carding machines. If oil is necessary to help with the spinning it's adding back in once the fibre has been processed. Next the wool is carded, as you can see there are multiple rotating drums, that pass the fibre from one to another, so it will only need one pass through the machine. Then the wool is taken off the drums as a sliver, and fed on to another machine which starts the process of drafting it out and making it ready for spinning. It comes off the machine in little cakes of pencil roving. Over in Iceland, the famous Lopapeysa sweaters are made by knitting with the fibre just as it is, before any further spinning is done. After that the cakes go upstairs and are mounted on the spinning frames. These frames move backwards on the rails you can see on the floor, each little blue blob is a shuttle, it rotates, adding twist to the drafted out fibre, and then as the machine rolls back to the starting point the spun yarn is wound on to the shuttle. It's all very similar to a traditional longdraw you do on your spinning wheel, except of course, much faster, and one machine produces far more than a handspinner could ever spin. It's no wonder that clothes ceased being luxury items at the time of the industrial revolution.

The museum also has collections of older spinning and weaving equipment, so I shall do part 2 and probably 3 sometime soon... I had my new camera with me and wanted to put it through it's paces! Comments are closed.

|

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed