|

After I got back from Summer School I had a hectic few days getting caught up, sending out club parcels, and restoring everything to its usual place. Before I went I'd built myself a new storage shed to hold all the undyed bases I hold in stock, but hadn't got any further in executing the grand reorganisation! After a period of time when it looked like it was never all going to fit, I've finally achieved the end goal. All the fibres associated with the business are now out of my house, and in to their own dedicated stock room. It's very nice to get some of my own space back, and I can tell already that it's making me better about splitting time between work and play, and taking time off. And once I was caught up, that's what I did. I've just had to go round taking bad photos, because when part of your job involves taking lots of photos, and part of your job is doing the social media stuff it's also really important that the down time doesn't carry on feeling like work. Of course the idea of sitting around for a few days doing nothing isn't my bag. So I did some sewing. Full confession time.... I did just pull these out of the washing basket for this photo, so they are looking somewhat crumpled. The fabric used an eco printing technique, I took this photo when we did a guild workshop in July, and it probably shows the technique more clearly than words. I learned how to do this at an association Sumer School in 2017. The pattern is Ultimate Pyjamas from Sew Over It, and I will definitely be using it again. You take various leaves, lay them out on a piece of fabric, wrap it up in to a bundle, and boil it for a while. The natural colours in the leaves leach out and leave a print behind. For my pyjama bottoms I gave the fabric a boil in rhubarb leaf mordant first, though I note that in a recent blogpost Jenny Dean (from whom I got the information), no longer really uses this method, however, it shifted the baby blue of my fabric in to a more please eau de nil shade. I also soaked my leaves in an iron solution, which acts as a mordant, and indeed will make a print by itself, so even if the rhubarb doesn't act as a mordant, my leaf prints should stick around for a while. There isn't really a definitive guide book to eco printing... but if you have a basic understanding of natural dyeing, then it's great fun to try. I really would recommend reading a reputable natural dyeing book first, natural doesn't always mean safe. The India Flint book on Eco Dyeing is a little wordy for my taste, not that helpful if you're trying to pick up what to do from scratch, and but is an interesting thing if you want to start experimenting further. The Jenny Dean book Wild Colour is a great book to use as a resource, and if you know it will dye then it's a reasonably safe bet that it will also make a print. I do what we did at Summer School which is to boil my bundle of cloth and leaves, but others use a steamer. I also did some fancier sewing.... not that you'd believe it from this photos, but I am just not in the mood to start trying to take selfie's today. So trust me when I say that this is the French Dart Shift Dress, and is made from some Liberty Linen I bought myself for my birthday present last year. It feels lovely to wear... and it has pockets! Again, I am definitely going to be making other visions of this. oMeanwhile on Planet Chicken. We have 2 boys and a girl from the first clutch. The boys are going to be Monty and Don, and are both gingery brown. (Only 1 of them is in the photo, the other was busy stuffing himself with mealworms.) Their sister is going to be called Gertie after Gertrude Jekyll. She's the blonde one in the photo above, and is being continually left behind by her big brothers. Their Mum (Niddy) has now left them to their own devices, and for a few days all you could hear was poor Gertie plaintively cheeping because she didn't understand why she had to look after herself. The other chick is also probably a girl, though it's always harder to tell when you don't have any other chicks of the same age for comparisons. Her Mum is looking after her much better, but hopefully all 4 youngsters will get along when Ebony decides she's had enough of parenthood. In keeping with our gardener theme for this years youngsters she's probably going to be Vita, after Vita Sackville-West. I am busy in planning mode at the moment. I am just starting to reveal the details for this years 12 Days of Christmas parcels. These will go on sale very shortly as I need to order the fibre to arrive before crashing out of the EU will cause the price of the fibre to rise, and also so I can send EU customers their parcels before October 31st so they don't end up paying tax twice. I still doing everything I can to make sure that I have a functional business over the coming months, but I am dealing with complete unknowns at the moment.

On a more cheery note, my final in-person event of the year will be Bakewell Wool Gathering on October 12th and 13th. This is a lovely smaller scale show, nearly in the middle of Bakewell itself, entrance is only £5, or £8 for a weekend ticket. In August last year I wrote a blogpost about some new packaging I was introducing. Since then I've also introduced using biodegradable clear grip seal bags. I much prefer to use these bags because they allow me to create a sturdier parcel, and they actually offer some protection to your order. You can carry on re-using these bags for a long time in the future. I can't see the point in wrapping up fibre in a piece of tissue paper. It serves no purpose, and in my experience of receiving orders it's often a tattered mess by the time the parcel has been squashed in the mail system. It's Reduce, Re-use, Recycle. In that order. The first step is to reduce, and for me, that means only using packaging that is useful. I receive a lot of my supplies by mail order, which means lots of packaging coming in to the house. Nearly all of this is re-used to send out orders from Mum and Dad's Etsy shops. Clear plastic sacks provide protection for large knittingbags that are sent in re-used cardboard boxes. Even larger plastic bags are used instead of bubble wrap to provide protection to wooden yarn bowls. There's always a certain amount that is not reusable, which is where this box comes in. I now pay a company called Terracycle for one of these big boxes. I stuff it full with all the plastic waste that our local council won't accept, and they turn it in to useful things. They even accept the clingfilm I use as part of my dyeing process.

Now this isn't cheap, this large box costs £230, and I am lucky in that my business is in a position where I can absorb that cost as part of my commitment to be more sustainable. On a related note, I have a decision to make about my outer mail bags. I can now get an option that are made from potato starch, and are home compostable. However, they are slightly translucent, so you can see the contents, and I have mixed feelings about using a food source for packaging. We have issues with food security on this planet, and there are issues with diverting food resources in to making packaging. And then there's the cost. 1000 of the smallest size outer mailer (made from recycled plastic with a biodegradable additive) I currently use costs me £114 1000 of the home compostable ones will cost £192 If I swapped to just using ones made from recycled material, but don’t break down I could buy 2500 for £120 If I went for non-recycled ones I could have 1000 for £50 The home compostable ones also have to be used with in 6 months, and at the moment I wouldn't manage to use a batch of 1000 quickly enough, so I'd have to buy a smaller batch, which is again, more expensive. We have to do something with all the plastic we send for recycling... and as it is there are issues with western countries currently not managing to recycle the plastics we produce. I've been thinking about this for a couple of months now, I'm just about to do a re-order of mailing bags, and I don't think there's actually a right answer. I know some businesses have switched to using paper, but I've decided not to do that as it's significantly heavier (so uses more fuel to transport), and paper production uses a lot of energy. And just as with using food starch to make bags there are issues about where all this paper is coming from. At the moment I am leaning towards continuing with my current option, the largest size bags will always have to be made from plastic as the corn starch isn't strong enough for the heavier parcels. All of which is to say, I am still working hard to keep my business as sustainable as possible. Even though at times it feels like a drop in the ocean. When I was at Summer School a couple of weeks ago the caterers were going to hand out bottled water with every evening meal. Thankfully we managed to persuade them to set up a water urn, and most people then used their own cup or mug, but they had no option to hold liquids other than disposable cups. In a week, 200 of us would have gone through a vast number of single use bits of plastic, and all because the college had removed it's dishwashing capabilities for anything that wasn't a plate or bowl.

Todays monthly blogpost comes to you from a hotel room just outside of York. I'm teaching at the Association of Guilds of Weavers, Spinners and Dyers this month, and have just finished setting up my classroom. The Trade Fair and Open Day is next Saturday, and if you're in the area do come along, for a look around all the classrooms.

The Baby Chicks of last month are now at the gawky teenager stage, and have been joined by a sole survivor from a second clutch of eggs. They are an utter delight and I am very sad to be missing them for a week. No names for this gang yet, I'm starting to get a feeling for which are cockerels and which are hens, but I've not picked the theme for this batch of names.

Speaking of the animals of the household... Quentin and Clarissa have been causing trouble again. There is a lengthy twitter thread sharing his latest exploits.

July is of course all about the Tour de Fleece, it's probably my favourite time of year, and seeing skein after skein of hands-on being produced over the 3 weeks is a real advocate for the power of just a little practise every day. One of the things I really enjoyed was this years Non-Wool Sample Pack. 19 different fibres ranging from silks, to cotton, to camelids, to baste fibres.

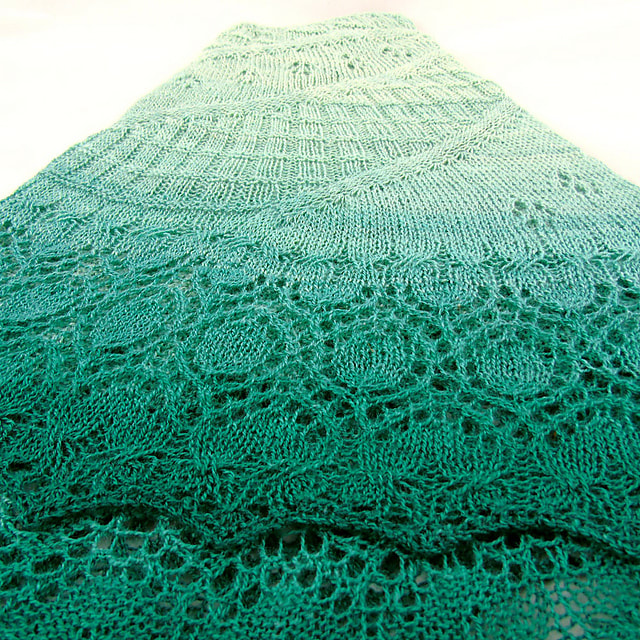

I am oh so very behind in writing this post... but I am finally in a position to work through my to-do list and get round to all the things that are on it that I wanted to do, but weren't urgent! Over in the Hilltop Cloud Ravelry group we have a community thread for people to share photos of their spinning, and finished objects. It's called Spin It, Knit It, Win It, but of course you're not limited to just knitting. It's one of my favourite places to browse in the mornings with a mug of tea, and is a huge source of inspiration. These are the highlights from the last round, but if you missed posting in that thread fear not, there's a new thread every 3 months and you can post in it at any time. If there's a Ravelry project/stash entry for the photo then clicking on the image will take you to the appropriate page. And while I'm writing a post that feature Ravelry projects, I am going to repeat here what I have already said on my various social media accounts. I am in complete agreement with Ravelry's decision to ban support for Donald Trump on their site. I am tired of trying to express kindness and tolerance towards individuals who support him, when their views display a complete lack of tolerance and kindness towards the individuals who are harmed by his policies. I have tried having polite discussions, but to use a well used analogy, it's like trying to play chess with a pigeon. They're not interested in opening their minds, and I'm no longer willing to share my space with them.

We're getting in to my favourite time of year. The garden is starting to come alive, the weather is warming up, and the days are blissfully long. After a winter of dashing from house to dye studio it's blissful to be able to stand at the top of the garden and feel the sun on my face. I've been out and about quite a lot over the last month, which has meant that the online shop hasn't had quite as many shop updates as is normal. However, I've nearly finished working on a commission project, and have got the first batch of Tour de Fleece team fibre sent out, so as we go in to June I should be able to ficus a bit more on the bread and butter work of dyeing lots of fibre in lots of colours! On a personal spinning note I've just finished a big batch of spinning for a cardigan. I'm not going to go in to too much detail, because I think it's deserving of it's own post with the technical information on spinning to specific grists for certain projects. However, I was rather pleased with the colour I dyed it with once the fibre was spun. I used some undyed Cambrian, and then dyed the yarn because I wanted this lovely glazed effect with a deep red with a wash of black over the top. The colour is going to go perfectly with some of my summer dresses, here's hoping I get the project finished before the warm weather disappears! This time last year we were just in the middle of sorting out leaking pipes that bring in our water supply, which eventually led to building our new rockery and pond...One year on, and we can see what survived the drought last summer, and the winter, so it was off to Aberconwy Nursery to fill in some gaps. If you're ever up on the north Wales coast this is a lovely little place, filled with some really unusual alpines. While we were up on the north coast we went to Plas Mawr in Conwy. This is a stunning Tudor town house, that is amazingly well preserved. I can't believe we've never been here before, but it's an absolute delight. One of my 2019 resolutions was to make more of the opportunities I get when I travel round the country teaching at workshops, so when I was teaching at Oxford Guild I came home in a slightly circuitous way, and spent a couple of nights on the outskirts of Milton Keynes, and went to Bletchley Park. I spent the whole day here, getting utterly immersed in the work of the World War II code breakers. By the end of it my brain hurt, I don't think I'd have been selected to work as a code breaker!

The Non-Wool section of the shop has continued to expand, and there are now lots of unusual fibres that are not commonly available in the UK. In particular one that I've not seen before is Wild Giant Himalayan Stinging Nettle. This fibre comes from Nepal, growing in the foothills of the Himalaya at heights of 1800-3000m. It can grow up to 3m in 1 yer, and the harvesting process actually encouraged the plant to put on better root growth which stabilises the soil structure. This reduced land slides and soil erosion. Local people do all the harvesting and scrutching, providing vital employment in this area in a way that encourages the protection of the local forests, as the plant will only grow when there is a tree canopy above it. It spins in a very similar way to Ramie, making a beautiful smooth, strong yarn that would be great for lace or summer tops. By now the UK parcels for the April Non-Wool Club have arrived, so I sat down and filmed some short video clips showing me spinning them. I am aware that these are probably not the most professionally shot videos in the world, but do hope you find them helpful. If you aren't a member of this club and are thinking about joining then I plan on opening up the next round of 3 month subscriptions at the start of May. The cost will be similar to the current prices for the club, though may alter slightly depending on the exact fibres I use. There will be some repeated fibres, but will be some new ones as well. These are the colours that are going to inspire the next round, if you're interested in joining then select the option on the poll below, I pre-order all the fibre required for this club before putting it on sale to make sure I have adequate supplies. So voting helps make sure I can meet demand. The colour options last time were inspired by the Italian landscape, and this time we're going to Spain. So with the admin out of the way, on to the videos and spinning hints. The first fibre that I recommend you start with this month is the mulberry silk. We spun 2 fibres last month that were similar, the tussah silk , and the viscose. If you still have your tussah silk, compare and contrast the 2 types, you may also find this old blogpost on types of silk useful. The main thing is to remember the staple length. Mulberry Silk is more like spinning a long wool, so a relaxed grip with you hand holding the fibre supply is crucial. I favour a short forward draw for my mulberry silk, without using too much twist, it maximises the shine and makes the yarn feel very soft and luxurious next to your skin. The next fibre I recommend you spin is the Ramie. Ramie is a bast plant fibre like linen, so hasn't needed the same level of chemical processing as that required for viscose of rayon. Ramie is processed from plants belonging to the nettle family; Boehmeria Nivea and Boehmeria Tenacissima. These plants grow incredibly quickly, they can reach a heigh of 2 or 3 metres and be harvested several times in a single year. When linen is processed you can remove the outer stem by hitting it, but this isn't possible with ramie, which is one of the things that contributes to the price. The inner stem is then treated with lye (the same chemical used to make soap) and that dissolves the pulpy material, leaving behind the fibrous vascular bundles. The fibre is then combed to make the length of top we're spinning from. The final fibre to spin this month is Hemp. This is a very ancient textile plant, one of the first to be spun in to yarn as long ago as 10,000 years. Unfortunately the familial connection with the plant that produces cannabis meant that this very useful, very ecologically sound textile was largely abandoned. The Hemp plant that is used for textile production is completely different to the plant that produces the THC chemical which is needed to produce a high or be useful on a medical basis. Hemp was commonly grown until the 1900's, but is now experiencing a revival particularly as it is one of the fastest growing plants, producing a crop very quickly, and requiring half the amount of water and yielding twice as much usable fibre as cotton grown in the same field. In the video I recommend reading the Flax edition of Ply magazine, this is available as a digital download and is well worth the money to get a sense of how to work with this bast fibre, as in essence you can treat flax (linen) the same way as the hemp. Finally some advice on finishing this yarn. I treated it as I would linen thread, and gave it a gentle boil in a washing soda solution, the yarn came out much softer and more flexible. I wanted to test it because this normally something that's done with undid thread, and I was a little concerned that the colour might leach out from the fibre. However, the water was slightly lilac, but not really enough for me to not recommend this method. I suspect for everyone reading it's felt like this month has been rather quiet.... But in reality it's been rather busy. I decided to get on with my dyeing for the stand at Wonderwool Wales so I knew if I was short of any particular fibre base. I also wanted to tick the job off my list. I suspect I'm not alone in finding that the political uncertainty is making me somewhat anxious, and getting the Wonderwool dyeing out of the way meant I had one less thing that I was worrying about. Speaking of political uncertainty, I always try to be respectful of people who have different political views than me, however I am going to come out and say this bluntly. Brexit will be a disaster for our country. It in no way allows us to "take back control" and leaving the EU will solve none of the fundamental issues with unfairness and lack of political representation in our country. On a very personal basis the British wool trade has never actually been just the British wool trade, it always relied on imports and exports, and this is no different now to how it was in medieval times. I use suppliers that are based in Europe, and even suppliers that are based in the UK are in turn reliant on manufacturing partners that are based in Europe. At the moment I still don't know how much it will cost when I re-order certain fibres, and that makes planning for the future impossible. We are already poorer as a result of Brexit and that will only get worse if crash out with no deal. Bank of England estimates that the British economy is already 2% smaller than it would have been if voters chose to remain in the EU. That translates to a loss to the UK economy of £800 million ($1 billion) a week' (Source- CNN) My first job was working for Britannia Building Society, the headquarters were based in my home town, and part of the first week training focused around what to do in the event of an attack by the IRA. The Good Friday agreement had been signed, but it was recent enough that the treat of a bomb was not one to be taken lightly. I am a comparatively young person but it's easy to forget that in my lifetime we have gone from the horrors of the Troubles, to a border that I got to ride over on horse back as part of my summer holiday without any problem. Brexit means an end to that peace, and I find that thought to be completely horrifying. So earlier this month I went on a protest march for the first time. I went down to London and was part of the Peoples Vote March on the 23rd. I am privileged in that I was in a position to attend, so felt that it was something I had to do. I am also lucky in that my MP (Liz Saville-Roberts) is one of the MP's who is coming out of this with her head held high. I know some pope would like to just read about spinning and look at pictures of my chickens, but all that is only possible if I earn money by selling fibre, and despite being very capable at running my business Brexit places my entire livelihood at risk. So I'm afraid I am not in a position to be able to just keep quiet and pretend that everything will be alright, because it won't. If you choose not to buy from me due to this position, then I am sorry that you will loose the pleasure of working with my fibres, but I will be even sorrier if I don't speak out to try and stop the catastrophe that will make all of us poorer. I know that many of you are not so blessed with your elected representative, if you've not sent them an email then please do so (form letter here asking for a people's vote on any final Brexit decision). Also, I'm going to share the link to the petition to revoke Article 50, and move on to happier topics! We had a bit of a soggy week in March, where the rain never seemed to stop falling. Thankfully the end of the month bought some beautifully sunny weather and we've dried out nicely and the garden is now starting to show all the signs of spring. There are tulips popping up everywhere, and we took advantage of the warm weather to check the bee hives for the first time this year. With the Wonderwool Dyeing complete I've been able to move on to getting the online shop a bit more sorted. There is a drying shed full of hand dyed fibre that I will be photographing tomorrow. I've also added lots more colours of Superfine Merino & Silk (this is one of the bases that comes from Europe and I am lucky that I am in a financial position to stock up now, there is no guarantee that future deliveries will remain at this price). In particular I've added quite a few very beautiful neutrals, those of you who got the 12 Days of Christmas parcels will recognise a few of the shades. And, there's a new fibre to add to the range. I've been thinking about this addition for a while, drooling over the colour palette in my shade cards, but not sure whether to take the plunge... But I made a decision, so there are now 7 colours of 19 micron Merino which has been naturally dyed. I hope you like them as much as I do. I've been busy with lots of personal projects as well... there's a freshly sewn top that's waiting for a photo, more lace shawls. the start of a new lino print to celebrate the arrival of spring, and some more tapestry weaving.

I know there are quite a few of you that love the hand turned wooden items that appear in my Dad's shop, and be wondering why there's not much listed at the moment.... he's fine, but now the owner of a new hip, which has finally been replaced. Hopefully he's going to be back on his feet in no time, not least because sympathetic nursing is not a personality trait that comes naturally to either my Mum or I! If you've not received your club parcel yet you may want to skip this post and come back later when your fibre has arrived. There are lots of new fibres in the club parcels, so It bought some video clips to give you some ideas on where to start would be helpful. If you want to see step by step instructions on how to attach a leader to your bobbin with a loop at the end then the blogpost is here. I recommend starting with the Tussah Silk. I like spinning it with a short forward draw from the end of the top, that way you get a super shiny yarn. The other way to try spinning silk is from the fold. You can use a short forward draw as before, or try doing a point of twist draw. Viscose is shiny fibre like the silk, but much more slippery. Try spinning the silk first! You can use a short forward draw to keep it smooth and sleek, or you can spin it from the fold. For the Baby Camel, check the staple length, that's what will catch you out after spinning 2 long staple fibres. You can spin it with a short forward draw, and it will also work well as a thicker yarn. Don't be afraid to use a good amount of twist with this short stapled fibre. It will also suit being spun from the fold, and this would probably be the method I'd pick to spin this fibre. And here are the fibres in the parcels this month.

Tussah Silk in the Antilles and Violet, Viscose in Fog and Shell, and Undyed Baby Camel. The club is full for this 3 month block, but I will be doing it again in the summer, and spare fibre from the parcels will go on sale in the shop in 1 months time. Tussah Silk is one of the more textured form of silk, if you're interested in knowing more about silk then I wrote a summary here a while ago. Viscose is an extruded cellulose fibre, it's also sometimes called Rayon. Celulose fibres are dissolved using chemicals, and are then extruded out in to very fine filaments that make up the fibre. This Viscose is made in China, but is purchased through a supplier who is committed ti ensuring environmental good practise. Both fibres were dyed to Okeo-Tex 100 standard in Italy. Baby Camel comes from the undercoat of young camels, and is incredibly warm and fluffy, most of the fibre comes from the Bactrian Camel (the one with 2 humps), and is sourced from China, Tibet and Mongolia. The busy months keep on rolling round. It was lovely to meet so many people at Devon Guild, and even better I got to take a few days off after the workshop exploring Exeter. I can thoroughly recommend it as a pace to spend a couple of days. The cathedral is magnificent, the museum delightful, and the Underground Passages were fascinating. I've been spending quite a lot of time on the computer this month doing lots of very dull behind the scenes work. The end is in sight however, and the work now should hopefully minimise a lot of the routine tasks I'll need to do in the future. The Non-Wool Club is nearly full, but I can still squeeze in a few more spaces, you've got a couple more days to sign up as I shall be starting to pack up the fibre next week at which point subscriptions will close. I'm also in the middle of transitioning the existing monthly clubs to a new payment system. The Gradient Club members are in the process of swapping over, and I'll be moving on to re-organising the Time Travellers club soon. I've also been dabbling in a new fibre craft. Tapestry weaving and woven wall hangings seem to be everywhere at the moment, and they're a great use for odds and ends of fibres. This cloud shape uses a frame loom from Weft Blown. I used lots of spare pieces from the Colours of Cambria packs, and some undyed Cambrian wool. Sometime I spun a length of 3 or 4m and used that to weave, in other places I used pieces of unspun combed top. I've also had a go at making a more traditional wall hanging. These little hangings are great fun to make, and really not that hard. I used a small frame loom I bought from Ebay for around £12. The rest of the fibre is a selection of colours from the Superfine Merino & Silk (Paradise, Thyme, Cinnamon, Fog and Cappuccino) with a piece of Silk Chiffon Ribbon (colour way Moss). If you're on Instagram then take a look at the hashtags #wovenwallhanging and #weavingloom to get lots of inspiration. If you want to have a go and don't know where to start then I used YouTube to teach myself most of these techniques. This playlist is really clear, she also explains how to make a loom using a picture frame and nails if you want to go down the DIY route. This playlist is another good one to use. If you're coming by the stand at Wonderwool I expect there might be quite a few of these on display! If you don't want to get sucked in to the rabbit hole of yet another craft then we're having a lovely time over in the Ravelry group doing an informal lace knit along, or crochet along if you prefer. You can pick any pattern so long as it has yarn-overs, and use any yarn, does't have to handspun, or Hilltop Cloud fibre. We've had poultry drama over the past few days... I came home from Devon to discover that Trotty had completely gone off her legs. Still bright and bubbly and wanting to stuff herself with tasty treats, but completely unable to walk. Two weeks in the house and she gradually got better and is now back out with the main flock. Unfortunately one morning we found the other newest chicken, Pippa, looking very unwell and she died a couple of hours later. The day before she had been running round with the flock very happily, but they're very good at disguising illness. Clarissa the duck has also been causing trouble (again), in addition to having escape skills that rival the Colditz prisoners, she tried to lay her first egg and couldn't, requiring an emergency trip to the vet and a paraffin enema. She's currently making her disgust at all things human known by absconding as soon as it gets light and spending all day as far away from the garden as possible. Sigh, that duck.... Yesterday was St Davids Day, the patron saint of Wales, so I celebrated by going for a bit of a jolly over to the coast, and had a thoroughly Welsh lunch out. It seems insane to say that 1 month on from my last blogpost I still don't know what will be happening with Brexit, and for now all I can do is keep on running the business as normal. I plan on sending out the Time travellers Club as early as possible to avoid any hold-ups at the ports, and also to make sure you don't get charged tax twice when you receive your parcel. I am still hopeful that this whole process will be halted and that common sense will prevail.

I do love seeing what people do with my fibre, and I know from so many people how inspired they get by the work of others. Over on the Ravelry group we have a thread that is just devoted to the sharing of pictures. There's no chat in the thread, so it's the perfect place to browse if you're short on time. Asa think you for sharing the photos I do a random number draw every 3 months, for gift certificates to the online shop. We've just got to the end of the time period of the current thread, so I thought I'd share a few of my favourites here. Clicking on the images will take you through to the Ravelry project page. |

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed