|

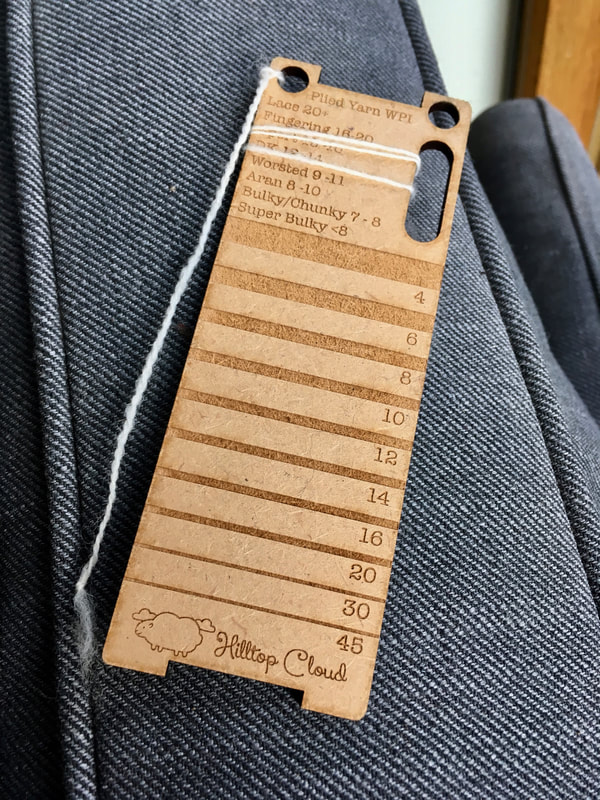

Back in June I posted a photo of some handspun yarn, and promised I would reveal all later on. A couple of months later and I've finished the knitting and have caught up with myself for longe enough to sit at the computer and write a blogpost. The yarn was actually spun for specific pattern, and I know it's something people struggle with, so I thought I'd document the process step by step. The pattern I wanted to make was Belmont. It's a cropped lace cardigan, and was a garment that was missing from my summer wardrobe, I tend towards longer length jumpers because in winter in a Welsh cottage you don't want a draft round your back. To start the process off I ordered a ball of the yarn that's used in the pattern. I don't always do this, but it's such a low cost yarn that it saved me a lot of sampling. If I can't get the yarn to go with the pattern then I'll just create more samples and swatches until I get to where I'm happy. So step 1 was to swatch with the original yarn, see how it behaved as fabric, and roughly what needle size I needed to get gauge. Then I spun some yarn that was the same thickness as the commercial yarn. However, I made a minor tweak. I increased the twist I gave to my singles, and therefore increased the plying twist. I wanted a yarn that is slightly harder wearing, though in part this is helped by using Cambrian Wool with it's lovely long staple length. A more tightly spun yarn will wear better. I washed my yarn in super hot water, and then knitted a swatch, my handspun in this swatch is at slightly fewer stitches per inch than that called for in the pattern, so I then did a further swatch with a smaller size needle. Again, more densely knit fabrics wear better, and the denseness of the fabric produced with the commercial yarn at the pattern gauge is slightly loose for my taste. Now the most important part of the process is the samples you keep from this step. They will allow you to spin the whole project at the same thickness as your original swatched sample. As you are spinning take some singles and wrap them round a sample card. You also need to keep a ply back sample to show how much plying twist you need and to monitor your spinning twist. As you spin you can go a quick glance to check the singles are roughly the same thickness, and on a regular basis do a ply back sample to check that the thickness is still correct, and that the plying twist of your payback sample matches the one on your reference piece. I set mine up on my wpi tool, but a piece of card is low cost version that works just as well. All these samples are unwashed, because you are comparing them to unwashed singles as you spin. Advert breaks are an excellent reminder to check your spinning, though setting a timer to go off every 15 minutes is also really helpful. Now if you've played around with the grist (this says how many grams of yarn you have per metre) the weight of yarn suggested in the pattern won't be accurate. However, the total yardage will still be the same. The results should be several skeins of yarn, all of the same thickness, and ones that should match your sample. In an ideal world, do another small swatch to check, but if you skip this step it's not generally disastrous. I spun my fibre in the white and then dyed it as yarn, so I could create this lovely glazed effect with a deep red, just washed over with a init of black. (Note to self however, remember to use loose ties if you're dyeing handspun!). In the photo below the main skein at the top is the dyed handspun, the single red strand is the Jamieson & Smith Shetland Heritage (the original pattern yarn), and the white skein is my original sample skein. Then I could set to with the knitting. after what felt like miles of twisted rib I got to play start on the lace pattern. Now this is where I was quite pleased with my decision to make a bouncier 2-ply yarn. The slightly rounder nature of my yarn means that the twisted rib sits beautifully, with the knit twitches sitting really proud of the ribbing. But the 2-ply structure still gave me a more open lace pattern. Want to know more about ply number and cables and lace... I wrote a blogpost a couple of years ago. Once finished it had a really good block, and I sewed on some vintage buttons.

|

Archives

January 2024

Categories

All

|

Hilltop CloudHilltop Cloud- Spin Different

Beautiful fibre you'll love to work with. Established 2011 VAT Reg- 209 4066 19 Dugoed Bach, Mallwyd, Machynlleth,

Powys, SY20 9HR |

RSS Feed

RSS Feed